|

Along with Okoume hull and deck test panels, I made a set of Meranti panels to evaluate using this option to build our Class Globe 5.80 #71. Specifically I was interested in the cost reductions associated with using less than half the resin and fibreglass compared to the Okoume option, and if there was a weight penalty by using the heavier Meranti plywood. For boats built with a 9mm plywood species other than Okoume, there is a laminate specification of 450g/m2 for the hull and 200g/m2 for the deck. I used the same criteria for selecting a laminate layup for the Meranti option as I did for the Okoume one. The fibres had to be easily sourced, have the possibility of adding a structural component, and contribute something positive towards to the finishing process.

0 Comments

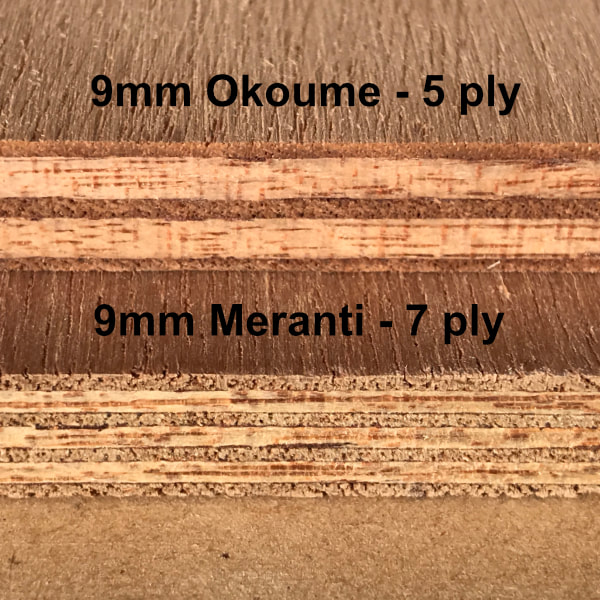

When I can, I like to check my guess work with real world examples. Although I have some general rules of thumb when it comes to estimating resin quantities for fibreglass jobs, I decided to make test panels to check the hull and deck laminate schedule for the Class Globe 5.80 yacht using both Okoume and Meranti plywood. The goal of making test panels was to understand how the different plywoods and laminate schedules could impact labour, weight and budget for this boat. I was not disappointed! The Okoume (also called Gaboon) plywood hull and deck structures have a specific laminate requirement. This is partly due to it being a fairly light weight and non durable hardwood which is relatively weak compared to other species. To compensate for these characteristics the 9mm thick hull panels require at least 1170grams/m2 of fibreglass and the 9mm deck panels 430grams/m2.

The plans do not have an actual laminate schedule listed, at least the type I am used to seeing, information such as fibre type, fibre orientation and weight per square meter. The designer has kept things very simple by specifying just weight per m2. This means that I can influence this part of the structure in a proactive way. I took a few things into consideration before committing to a laminate layup. I am aware that not only are Leanne and I building boat #71 and that I am very comfortable with the fibreglassing process, as the New Zealand kit agent I had to keep in mind that there will be builders with no previous experience using these products and learning as they go and that I would be asked for recommendations on materials. I decided that the products had to be common and readily available, I wanted to enhance the strength or stiffness of the hull if possible, and I wanted to impact the finish in a positive way all without making it too complicated. Following is my conclusion: |

|